Devon-based clean tech company Altilium has launched a crowdfunding campaign to support the continued scale- up of the company’s pioneering EV battery recycling technology.

The Series B1 funding extension is in partnership with Republic Europe (formerly Seedrs), the online private investing platform.

The move follows Altilium’s recently closed Series B raise, led by Japanese trading group Marubeni Corporation and Mizuho Bank.

With its proprietary EcoCathodeTM process for recovering battery materials from EV waste, Altilium is helping to build a sustainable domestic supply chain of critical raw materials in the UK, reducing dependency on imported materials and supporting industrial resilience and economic growth.

The crowdfunding campaign marks a key step in Altilium’s mission to build a circular economy for EV batteries, enabling engagement with local communities, as well as building visibility for recycling at a national level. It will also provide an opportunity to reconnect with early backers from the company’s successful 2022 crowdfunding round.

Dr Christian Marson, co-founder and COO at Altilium, said: “This crowdfunding campaign is about more than raising capital – it’s about building a community of supporters who believe in a cleaner, more sustainable future. We’re incredibly proud to have the backing of major international groups and excited to now open the door to individual investors who want to be part of our growth story.”

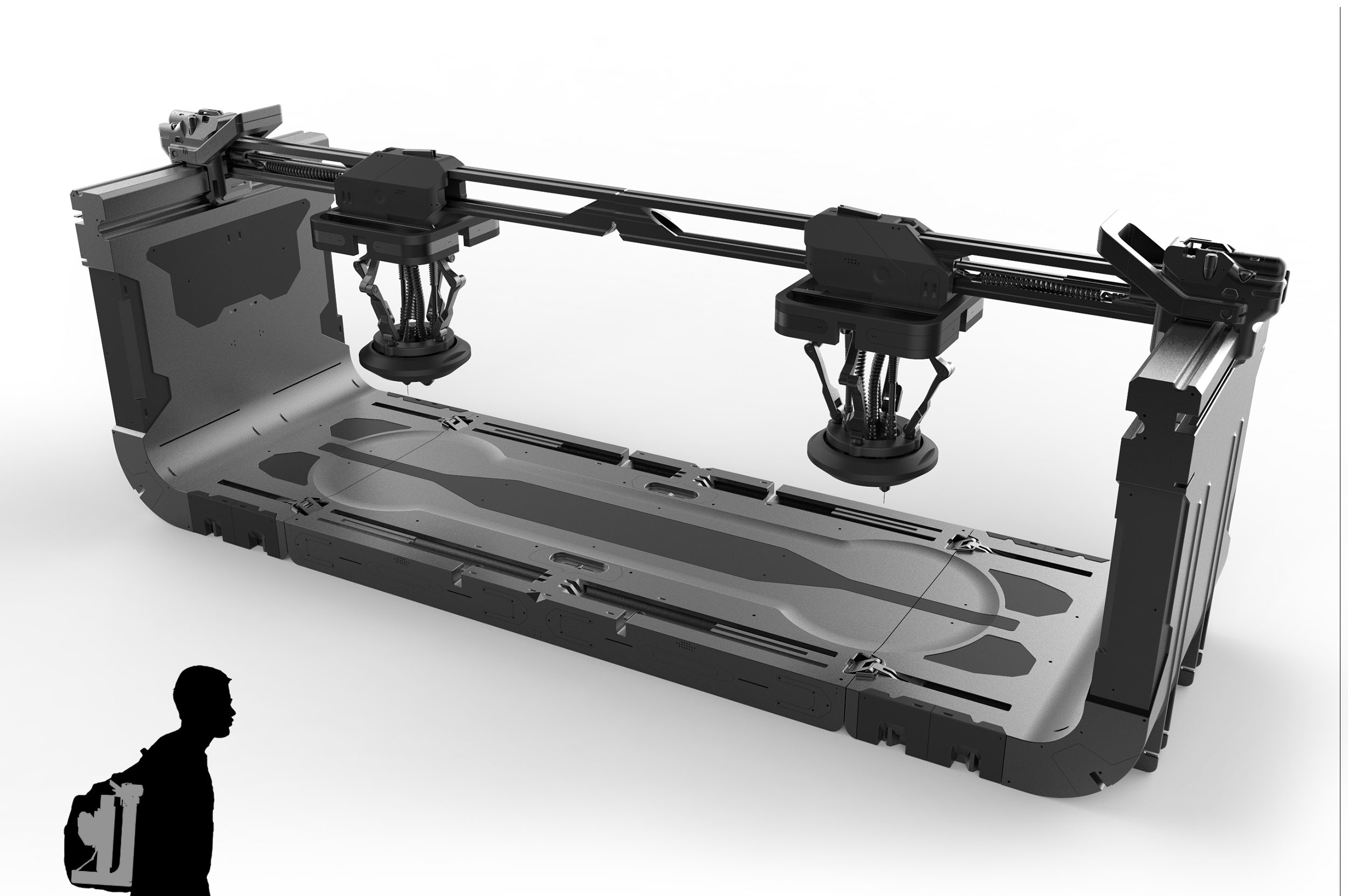

Founded in 2020, Altilium has quickly grown into one of the leading clean technology companies in the South West, with teams working across three locations in Devon, including its ACT 2 recycling facility in Plymouth, the first of its kind in the UK.

The company recently began work on its new ACT 3 scale-up plant, also in Plymouth, while its ACT4 mega-scale recycling facility is now in the final stages of planning. The plant will have capacity to process scrap from over 150,000 EVs per year, producing 30,000 tonnes of cathode active material (CAM), meeting nearly 20% of the expected demand in the UK by 2030.

Previous Article

Next Article